DuBois & King was recognized for outstanding examples of engineering excellence for three projects in the 2014 Engineering Excellence Awards sponsored by the American Council of Engineering Companies/Vermont Section. ACEC/VT annually sponsors an Engineering Excellence Awards Program to showcase exemplary engineering projects completed in Vermont. A panel of judges, comprised of distinguished planners, engineers and construction professionals, selects award winners from entries submitted. The winners of the competition were announced at the Annual Engineers Week Banquet on February 21.

DuBois & King was recognized for outstanding examples of engineering excellence for three projects in the 2014 Engineering Excellence Awards sponsored by the American Council of Engineering Companies/Vermont Section. ACEC/VT annually sponsors an Engineering Excellence Awards Program to showcase exemplary engineering projects completed in Vermont. A panel of judges, comprised of distinguished planners, engineers and construction professionals, selects award winners from entries submitted. The winners of the competition were announced at the Annual Engineers Week Banquet on February 21.

DuBois & King received the highest ranking and a Grand Award in the Buildings and Structures Category for structural engineering services for the new Dion Family Student Center and Quad Commons Residential Hall at Saint Michaels College in Colchester. The $24M expansion included a four-level, 39,900-sf student center, a five-level, 43,700-sf residential hall, and a one-level structure connecting the student center and residential hall. The structural design facilitated the dramatic interior and exterior architectural design that emulates Gothic arches, evoking a tie to the historic roots of Saint Michael’s College. The structural engineers utilized Building Information Modeling (BIM) to concurrently integrate the structural design with the architectural design and other engineering disciplines.

DuBois & King received the highest ranking and a Grand Award in the Buildings and Structures Category for structural engineering services for the new Dion Family Student Center and Quad Commons Residential Hall at Saint Michaels College in Colchester. The $24M expansion included a four-level, 39,900-sf student center, a five-level, 43,700-sf residential hall, and a one-level structure connecting the student center and residential hall. The structural design facilitated the dramatic interior and exterior architectural design that emulates Gothic arches, evoking a tie to the historic roots of Saint Michael’s College. The structural engineers utilized Building Information Modeling (BIM) to concurrently integrate the structural design with the architectural design and other engineering disciplines.

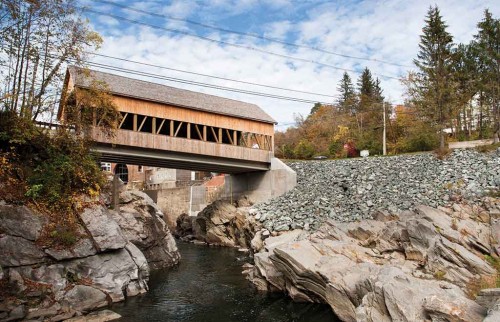

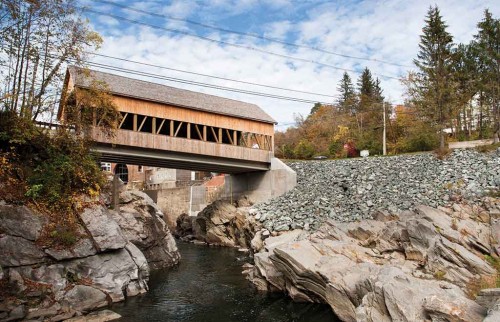

The Quechee Covered Bridge, in the Village of Quechee was severely damaged and impassable as a result of Tropical Storm Irene. The bridge is a landmark for the community and a vital transportation link connecting the Village business district and US Route 4. DuBois & King received an ACEC Engineering Excellence Merit Award in the Transportation Category for designing a replacement structure on a fast track schedule that restored this vital piece of transportation infrastructure back into service. The design, from concept to contract documents, was developed in four months. The design of the new structure is a combination of a traditional timber-framed cover with a concrete deck, beams, and abutments. The combination of materials increased the bridge’s durability and strength and was more economical compared with an all timber structure. The new bridge was designed with an increased span length and an increased hydraulic opening allowing another storm equivalent to Irene to pass without damaging the bridge.

The Quechee Covered Bridge, in the Village of Quechee was severely damaged and impassable as a result of Tropical Storm Irene. The bridge is a landmark for the community and a vital transportation link connecting the Village business district and US Route 4. DuBois & King received an ACEC Engineering Excellence Merit Award in the Transportation Category for designing a replacement structure on a fast track schedule that restored this vital piece of transportation infrastructure back into service. The design, from concept to contract documents, was developed in four months. The design of the new structure is a combination of a traditional timber-framed cover with a concrete deck, beams, and abutments. The combination of materials increased the bridge’s durability and strength and was more economical compared with an all timber structure. The new bridge was designed with an increased span length and an increased hydraulic opening allowing another storm equivalent to Irene to pass without damaging the bridge.

In the category of Special Projects, DuBois & King received an Engineering Excellence Merit Award for a $2.9M electrical upgrade project at the VA Medical Center in White River Junction. The Medical Center consists of 88 buildings on a 64-acre campus that serves 75,000 veterans in Vermont and New Hampshire. The electrical infrastructure of the White River Medical Center was outdated, inefficient, and non-compliant with current standards. The electrical upgrades addressed more than 300 electrical system deficiencies to achieve campus-wide improvements in reliability, serviceability, safety, energy efficiency, and emergency power. More than 1600 interior light fixtures and 145 exterior fixtures were replaced with high-efficiency LED lighting. Relative to energy and cost savings, the lighting upgrades alone resulted in an estimated annual cost savings of $49,500 and reduced electrical energy usage by 495,000 kilowatt hours. The electrical deficiency upgrade design had to comply with 23 separate codes and standards. Complex, detailed construction phasing was developed as part of the construction documents to assure that all active areas of the Medical Center would continue to function without interruption during construction.